Bambu Lab PET-CF Filament 1.75mm - Black 1kg/500g

Related Products

Bambu Lab H2D 3D Printer - ETL Certified (Pre-Order Available Now)

$3,099.00

Pre-orders are now available! The delivery timeline for this item has not yet been confirmed. Place your pre-order now to reserve your spot as orders will be processed on a first-come, first-served basis. Rethink Personal Manufacturing Explore Dual-Nozzle Capabilities Multi-material PrintingFlexible and rigid, low cost and exotic materials...

Bambu Lab X1 Carbon Combo - 3D Printer - cTUV Certified

$1,699.00

Bambu Lab X1 Carbon Combo Product Features Multi Color & Multi Material Capability High quality printing with 7 μm Lidar Resolution High speed CoreXY with 20000 mm/s² Acceleration Dual Auto Bed Leveling What to Expect from the X1C Combo 3D Printer Core XY with 20000 mm/s² acceleration Up to 16 multi-color printing Dual auto bed leveling...

Bambu Lab X1E 3D Printer - cTUV Certified

$3,199.00

Available now, please contact our sales team: sales@digitmakers.ca GET $100 Filaments Credit With Your Purchase Bambu Lab X1E with AMS The X1E offers the option to connect to your devices through its newly added Ethernet port, ensuring robust network communication in complex environments. Ethernet connectivity can also be used in crowded wire...

Bambu Lab P1S Combo 3D Printer - cTUV Certified

$999.00

Bambu Lab P1S Combo 3D Printer Product Features Works right out of the box, set up in 15 minutes Well-polished hardware and software Enclosed-body for high-temperature filament printing Up to 16-color printing with AMS Up to 20000 mm/s² acceleration, prints a benchy in 18min Built-in camera for remote monitoring and timelapse All-around perf...

Bambu Lab PLA Basic Filament (With Bambu Reusable Spool) 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Basic Filament (With Bambu Reusable Spool) 1.75mm - 1kg (Various Colors)

$29.99

BULK SALE PRICE Product Features Easy to Print & Beginner Friendly Smooth Surface Finish Biodegradable Diameter: 1.75mm +/- 0.03mm Recommended Printing Settings Drying Settings (Blast Drying Oven) 55 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, with Desiccant) Nozzle Temperature 190 - 230 °C Bed Temperat...

Bambu Lab PLA Basic Gradient 1.75mm - 1kg (Various Colors)

$31.99

Soft Bicolor Gradient Appearance The soft transition between two colors creates a vibrant and stunning visual effect on printed models. Display of Gradient Prints Gradient colors make it ideal for printing pretty toys or decorations. High printing speed with delicate finish Up to 300mm/s (with 0.4mm nozzle) printing speed while maintaining delic...

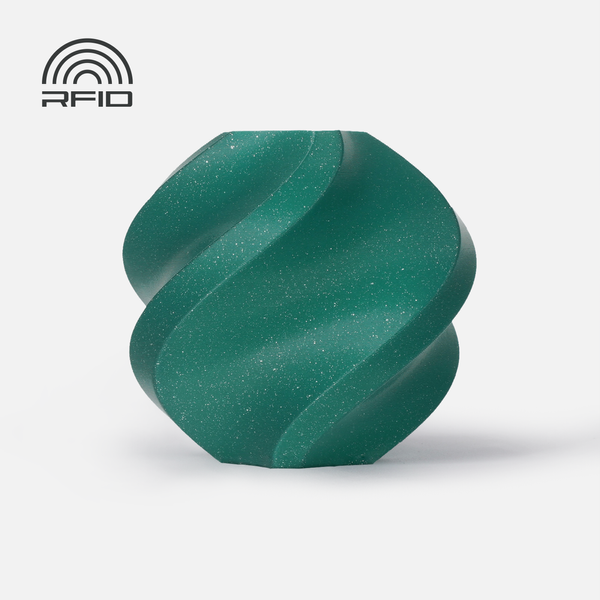

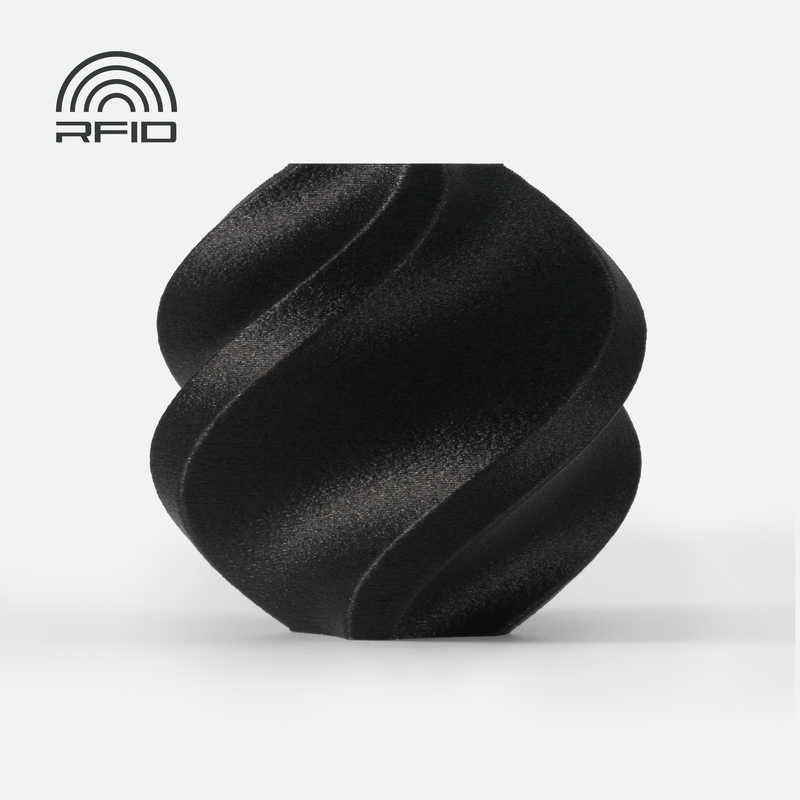

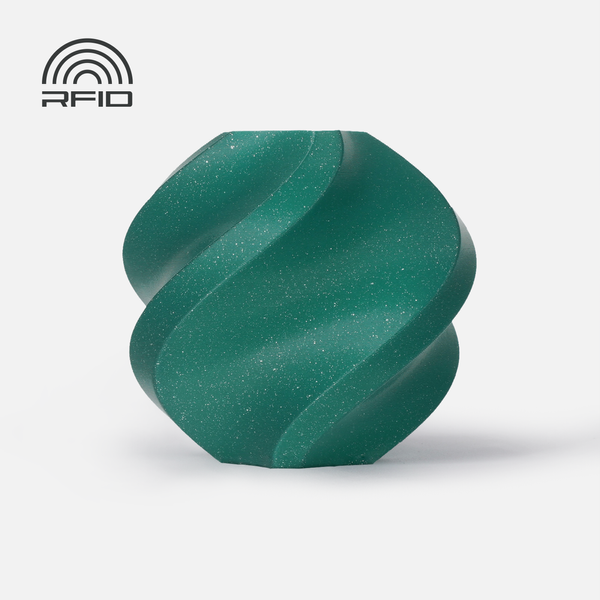

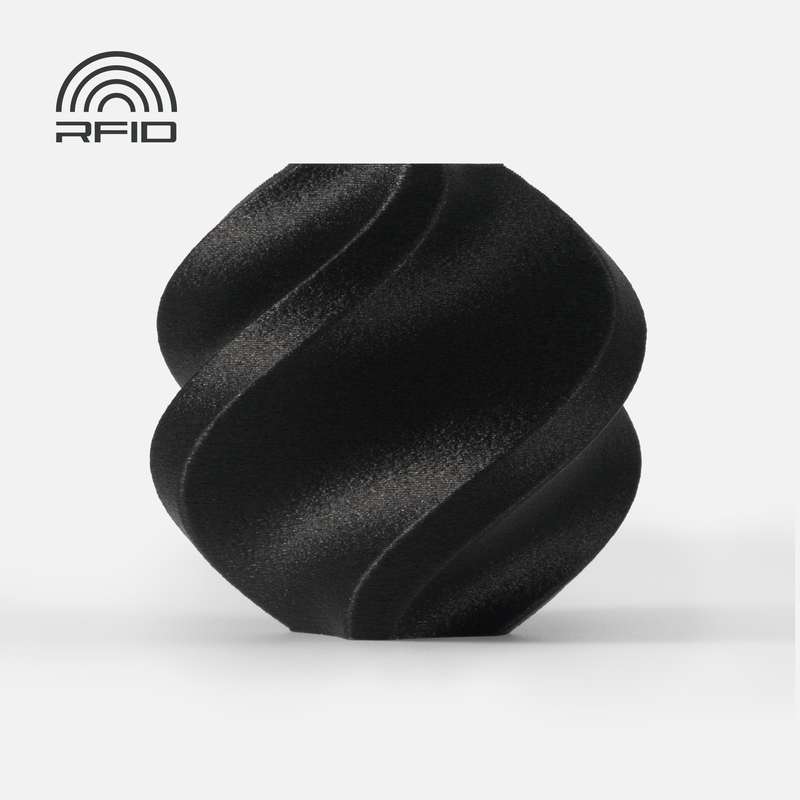

Bambu Lab PLA Sparkle 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Sparkle 1.75mm - 1kg (Various Colors)

$31.99

Bambu PLA Sparkle Bambu PLA Sparkle is a next-level aesthetic filament that combines strength and sparkle. With metal particles included in its composition, Bambu PLA Sparkle adds a special sparkling look to your prints that sets them apart from the rest. However, it is not recommended to use a 0.2 mm nozzle for printing as clogging may occur. T...

Bambu Lab PLA Aero Filament 1.75mm - 1kg (Various Colors)

$57.99

Bambu PLA Aero Bambu PLA Aero achieves low density and light weight by foaming at high temperatures during printing and creating small holes inside the prints. It's the perfect choice for light-weight and energy-saving prints, including unmanned aerial vehicles (UAVs), aerodynamic models, and gliders. Foaming PLA materials (PLA Aero) have high r...

Bambu Lab PLA Silk Filament 1.75mm - 1kg (Various Colors)

$31.99

Bambu PLA Silk Bambu PLA Silk offers a silk-like and high-glossy that adds a luxury appearance to your prints while retaining PLA's ease of use. Different with other silk filaments, Bambu PLA Silk was toughened and demonstrates greater resistance to breakage when using AMS printing. It's ideal for decorations, artistic projects, and 3D character...

Bambu Lab PAHT-CF Filament Black 1.75mm - 500g/1kg

$120.99

Carbon Fiber Reinforced High Temperature Nylon Bambu PAHT-CF Bambu PAHT-CF is a composite of PA12 and carbon fiber. Inheriting the advantages of low water absorption from PA12 and high-performance carbon fiber, Bambu PAHT-CF offers excellent mechanical and thermal properties that can be maintained well even when the prints get wet. Higher Z adhe...

Bambu Lab MC Board - X1 Series

$95.99

Compatibility X1C Overview MC board is the abbreviation of the machine controller board. It is the control center for the XYZ-axis motors, the cooling fans, the heat bed, and the AMS. In the Box - MC Board*1 Product Specifications Materials Metal, Ceramics Color Black Packaging Weight 0.1 kg Packaging Size 100*135*45 mm

Bambu Lab Complete Hotend Assembly with Hardened/Steel Nozzle (Various Size) - P1 Series

$51.99

Compatibility P1 Series Exclusive 0.2mm NozzleOptimal Print Fineness Extremely small layer gaps More detailed on the vertical print surface Smaller diameter extrudes thin filaments High resolution on the horizontal print surface 0.6mm and 0.8mm NozzleFaster Print Speed Larger diameter extrudes more filaments per second, resulting in faster pri...