- Home

- Fiber Reinforced

- Bambu Lab PPS-CF Filament 1.75mm - 750G

Bambu Lab PPS-CF Filament 1.75mm - 750G

Related Products

Bambu Lab PPA-CF - Black

Bambu Lab PPA-CF - Black

$181.99

Bambu PPA-CF Bambu PPA-CF, a premium fiber-reinforced nylon, delivers industrial-grade printing quality with precise 1:1 reproduction. Renowned for its exceptional mechanical properties and reliable performance in humid or high-temperature environments, Bambu PPA-CF is ideal for engineering applications, from mechanical prototypes to automotive ...

eSUN ABS-GF - 1.75mm 1kg - Various Colors

$39.99

Adding glass fiber reinforced materials to ABS and modifying, it strengthens the rigidity and toughness of ABS, it has excellent impact resistance and chemical corrosion resistance, and has good performance in scenes with high strength requirements such as some tooling and fixtures; Features Matte Texture Wear Resistance Chemical Resistanc...

FormFutura STYX PA6-CF15 - 1.75mm 500g - Black

$72.99

STYX PA6-CF15 STYX PA6-GF30 combines all benefits of STYX PA6 filament with its excellent mechanical, chemical and hygroscopic properties, plus 15% carbon fibers. STYX PA6-CF15 is a high-performance carbon fiber reinforced PA6 filament.The use of high modulus carbon fibers result in an unmatched strength and stiffness. This engineering fi...

FormFutura STYX PA6-GF30 - 1.75mm 500g - Black

$72.99

STYX PA6-GF30 STYX PA6-GF30 combines all benefits of STYX PA6 filament with its excellent mechanical, chemical and hygroscopic properties, plus 30% glass fibers. STYX PA6-CGF is a high-performance glass fiber-reinforced PA6 filament. The added glass fibers make this filament strong and stiff, without being brittle. This engineering fila...

eSUN PETG-CF Filament 1.75mm 1kg - Black

$34.99

ePETG-CF Carbon Fiber Reinforced PETG Adding carbon fiber reinforced materials to PETG and modifying, it strengthens the rigidity and toughness of PETG. Features High strengthWear resistanceImpact resistanceChemical resistance

FormFutura ApolloX CF10 - 500g 1.75mm

$59.99

ApolloX CF10 is a modified ASA based 3D printer filament with improved mechanical properties and is suitable for 3D printing mechanical parts and outdoor applications with high precision and zero warping. High Speed Compatible 350mm/s With high speed 3D printing becoming more prominent due to the introduction of high speed 3D printers, ...

ESun ePA CF Natural Black - Carbon fiber Reinforced Nylon 1.75mm 1kg Spool

$59.99

Product Description: Carbon fiber reinforced nylon filament High Strength, High Rigidity, Good Toughness, Wear Resisting Good flame resistance, Flame-retardant Level: UL94-V2; Print temperature range: 240~260℃ Print Base temperature: 80℃ Print Speed:30-60 mm/s; Move Speed:90-150mm/s Net weight : 1 kg Filament Size :1.75 mm Product Features...

eSUN ABS-CF - 1.75mm 1kg

eSUN ABS-CF - 1.75mm 1kg

$49.99

ABS Carbon Fiber Adding carbon fiber reinforced materials to ABS and modifying, it strengthens the rigidity and toughness of ABS. eABS-CF has excellent impact resistance and chemical corrosion resistance Description Adding carbon fiber reinforced materials to ABS and modifying, it strengthens the rigidity and toughness of ABS. eABS-CF ha...

D3D PETG Carbon Fiber 1.75mm 1kg Black

D3D PETG Carbon Fiber 1.75mm 1kg Black

$39.99

Polyester PETG premium filament. It is a rigid, tough, high performance material offering excellent clarity, light transmission and high gloss. Carbon Fiber reinforced PETG is made from Carbon Fibers infused with our trusted original series PETG 3D printer filament which is our popular, tried and tested thermoplastic filament. This PETG is re...

eSUN ePAHT-CF (ePA6-CF) High Temperature Nylon Carbon Fiber - 1.75mm 750g Spool Natural Black

eSUN ePAHT-CF (ePA6-CF) High Temperature Nylon Carbon Fiber - 1.75mm 750g Spool Natural Black

$99.99

ePA6-CF has been renamed to ePAHT-CF. Both names refer to the same product. ePAHT-CF (nylon carbon fiber) is a material jointly developed by eSUN and LUVOCOM. Compared with PA66, the size and electrical properties of ePAHT-CF are less affected by humidity and temperature. The strength of ePAHT-CF is higher than other eSUN nylon series prod...

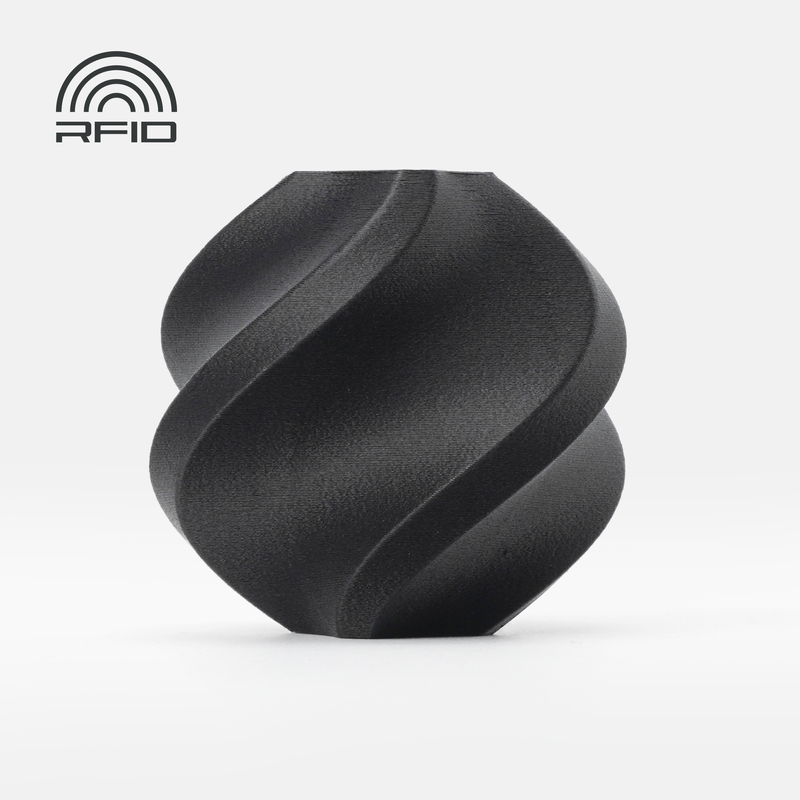

Bambu Lab PETG-CF Filament 1.75mm - 1 kg

$44.99

PETG-CF Carbon Fiber Reinforced PETG Product Features Less Clumping and Stringing Premium Print Surface Improved Mechanical Properties & High Flexibility Comes with Basic Reusable Spool Diameter: 1.75mm +/- 0.03mm Cautions for Use 0.2 mm Nozzle Not Compatible Stainless Steel Nozzle Not Recommended Dry before Use for the Highest Print Qual...

Protopasta High Performance HTPLA - Carbon Fiber - various colors

$49.95

Proto-pasta's High Performance Carbon Fiber HTPLA-CF combines engineering-grade performance with the ease and environmental-friendliness of PLA printing. Compared to ABS, PET, and similar Polyester materials, HTPLA-CF has: Better and more reliable printing No heated bed required Lower printing temperatures, simillar to standard PLA Les...