- Home

- FormFutura ApolloX CF10 - 500g 1.75mm

FormFutura ApolloX CF10 - 500g 1.75mm

Related Products

Filaments Depot PLA 1.75mm 1kg

$24.99

Filaments Depot PLA is quality virgin PLA. Both PLA resin and colorant are food-grade material. Made in Canada, Ontario utilizing sophisticated extrusion equipment and high-tech drying technology. The filaments are monitored with live multi-axis micrometer, and computerized diameter monitoring technology, producing clean, repeatable an...

eSUN PLA+ Filament 1.75mm 1kg - 27 Colors Available

$25.99

Please note: Depending on the stock level, you may receive plastic spools or cardboard spools. The high quality of the filaments remain the same. eSUN PLA+ "Skin" has been renamed to "Beige," as both refer to the same product. To reduce waste, try our Spooless Refilament ESUN PLA+ Available HERE We also sell eSUN PLA+ Black/White/Grey in 3k...

D3D Premium PLA 1.75mm - 1 kg- Various Colors

D3D Premium PLA 1.75mm - 1 kg- Various Colors

$24.99

1kg (2.2lbs) spool of D3D premium PLA filament that comes with a resealable bag and a desiccant pack. D3D Wood PLA is available too. Our D3D Premium PLA filament is made by Ingeo 4043D Biopolymer. It is easy to use and nontoxic. Made with bio-degradable materials derived from renewable resources. 50 colours available! (Click Here) for Pa...

D3D Sigma PLA 1.75mm 1kg - 34 Colors

D3D Sigma PLA 1.75mm 1kg - 34 Colors

$17.99

To make the cardboard spool compatible with Bambu Lab AMS, use this spool sleeve / cardboard rings. 1kg (2.2lbs) spool of D3D Sigma is Standard PLA filament vacuum sealed with a desiccant pack. The colour-changing filament changes colour thermally (orange, when below 33 degrees Celsius; yellow, when above 33 degrees Celsius). D3D Sigma is ano...

D3D PLA Refill - Bambu Lab Spool Compatible - 1.75mm 1kg - Various Colors

$23.99

PLA Refill BAMBU LAB REUSABLE SPOOL COMPATIBLE Neat winding D3D PLA Refill line up neatly, to avoid problems such as card wire winding brought about by poor printing. High precision Keep the stable tolerance in +/-0.02mm, no clogging and ensure the great 3D printing effect. Easy to print D3D PLA Refi...

D3D PETG Refill - Bambu Lab Spool Compatible - 1.75mm 1kg - Various Colors

$23.99

D3D PETG Refill BAMBU LAB REUSABLE SPOOL COMPATIBLE D3D PETG Refill is a high waterproof material, which makes it an excellent choice for outdoor prints. It also has excellent chemical resistance, which can be well-used in both acidic and alkaline environment. Moreover, PETG Filament also have strong impact resistance performance, which ...

Filaments Depot Low Gloss PETG

$29.99

First Time In Canada Introducing our new low-gloss PETG 3D filament. Made from high-quality PETG material with European- developed organic based matte agent. Low-gloss is durable and easy to print with, ensuring a smooth and reliable printing experience. With its low-gloss finish, it reduces the reflection and glare of light, giving your part...

eSUN PETG Filament 1.75 mm 1kg Spool Various Colors

$25.99

We also sell eSUN PETG Black/White/Grey in 2.5kg Availability of clear spooled PETG filaments dependent on stock levels. Made by E-Sun Polyester PETG premium filament. It is a rigid, tough, high performance material offering excellent clarity, light transmission and high gloss. The usage of PETG is comparable to the Taulman brand "T-Glase" fila...

eSUN ABS+ Filament 1.75 mm 1kg Spool - Various Colors

eSUN ABS+ Filament 1.75 mm 1kg Spool - Various Colors

$22.50

Please note: eSUN PLA+ is transitioning to cardboard spools. Depending on the stock level, you may receive plastic spools or cardboard spools. The high quality of the filaments remain the same. "eSUN ABS+ Skin" has now been renamed to "eSUN ABS+ Beige" and refer to the same color. ABS+ filament Provides: Less warping. Lower extrusion tempe...

D3D Premium Matte PLA Filament 1.75mm, 1kg Spool

D3D Premium Matte PLA Filament 1.75mm, 1kg Spool

$24.99

New Low-Gloss Matte PLA! 1kg (2.2lbs) spool of D3D premium PLA filament that comes with a resealable bag and a desiccant pack. Please note this material is high Density Material. The printed part will be heavier than regular PLA material . Please print it with Lower speed to ensure layer adhesion and matte finish. Our D3D Premium Matte PLA fil...

eSun eSilk PLA Filament 1.75mm 1kg Spool Various Colors

$29.99

eSUN’s eSilk PLA Filament uses a polyester-like additive to offer soft printed parts with a silky smooth and glossy finish, The new eSilk comes in different colors and it maintains Esun's high quality and dimensional material accuracy. eSUN PLA+ is transitioning to cardboard spools. Depending on the stock level, you may receive plastic spools or...

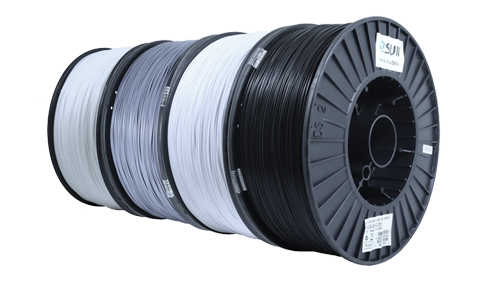

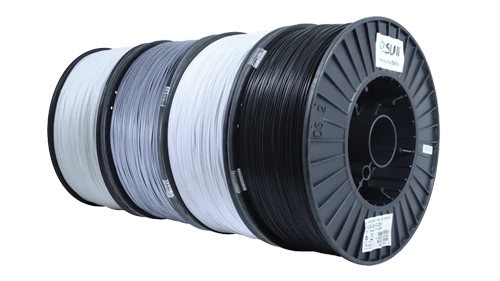

eSUN PLA+ Black/White/Grey 1.75 mm 3kg Spool

$73.49

To print your own spool holder, see HERE To purchase a modular spool holder that can be oriented anywhere, see HERE Made by E-Sun Spool Dimension Outside Diameter: 270 mm Inside Diameter: 50 mm Width: 100 mm PLA+ is 100% biodegradable and environment friendly. PLA+ Advantages: Blended with special bio-degradable bio-polyesters. High rigid...