- Home

- WAX Cast 3D Printer Filament -2.85 mm

WAX Cast 3D Printer Filament -2.85 mm

Related Products

EinScan HX 3D Scanner Hybrid LED and Laser Light

EinScan HX 3D Scanner Hybrid LED and Laser Light

$12,999.00

Based on years of 3D measurement experience and market demand, SHINING 3D innovatively integrates blue LED light and blue laser into EinScan HX handheld 3D scanner. The hybrid laser and LED light sources make EinScan HX compatible with a wider range of object sizes, meeting multiple needs of users. High efficiency and reliable results give EinSc...

EinScan H 3D Scanner

EinScan H 3D Scanner

$6,499.99

With more than a decade of accumulated experience in 3D vision technology, SHINING 3D is now introducing its newest development in 3D scanner technology, EinScan H. Based on hybrid structure light technology of LED and invisible infrared light, EinScan H is making human face scanning more comfortable without strong light. With a built-in color c...

EinScan Pro HD

EinScan Pro HD

$9,900.00

EinScan Pro HD Now in stock now at our warehouse in North York. Improves the Efficiency of High-quality 3D Modeling Impressive high resolution for fine details Handle dark and casting metal surface with less limitations Fast scan speed for high efficiency Inherited multi-functional and modular design of EinScan Pro series handh...

EinScan Pro 2X 2020 3D Scanner

EinScan Pro 2X 2020 3D Scanner

$6,998.99

The Einscan Pro 2X 2020 can be purchased with the Industrial Pack or Reverse Engineering Design Bundle. The Industrial Pack converts it from handheld to automatic scanning. Includes turntable, tripod, mount and electrical components. The Reverse Engineering Design bundle includes the Industrial Pack and Geomagic Essentials. Color Pack sold sep...

EinScan-SP 3D Scanner

EinScan-SP 3D Scanner

$2,975.00

EinScan-SP (Platinum) Ensures Designers Access to a Fast, Accurate & Reliable 3D Digital Experience Faster Scanning & Higher Accuracy EinScan-SP Provides a Higher Accuracy of 0.05mm for a Single Scan The Next Step in the Evolution of Desktop 3D Scanners Multi-functional, Capture 3D Data Easier and Faster Dua...

Raise3D E2 3D Printer

Raise3D E2 3D Printer

$2,750.00

Available Now For Extended Warranty on Raise3D 3D Printers, please take a look at RaiseShield. Shipped From Ontario , Canada All 3D Printers are Certified by Ontario Electrical Authority Third Party with a sticker at the back of the printer Industrial grade components printer that is ready for short-run manufacturing. Runs continuously w...

Kimya PEKK-A Amber 3D Filament

Kimya PEKK-A Amber 3D Filament

$614.99

The PEKK-A filament is intended for technical applications requiring a high resistance to temperature (up to 260 ° C). HEAT RESISTANCE ABRASION RESISTANCE CHEMICAL RESISTANCE FLAME RETARDANT – UL94 V0 Kimya’s 2-year warranty. Diameter : 1.75mm Poids Net : 500g Color : amber TECHNICAL SPECIFICATIONS DOWNLOAD THE PEKK-A KIMYA TECHNICAL DATA S...

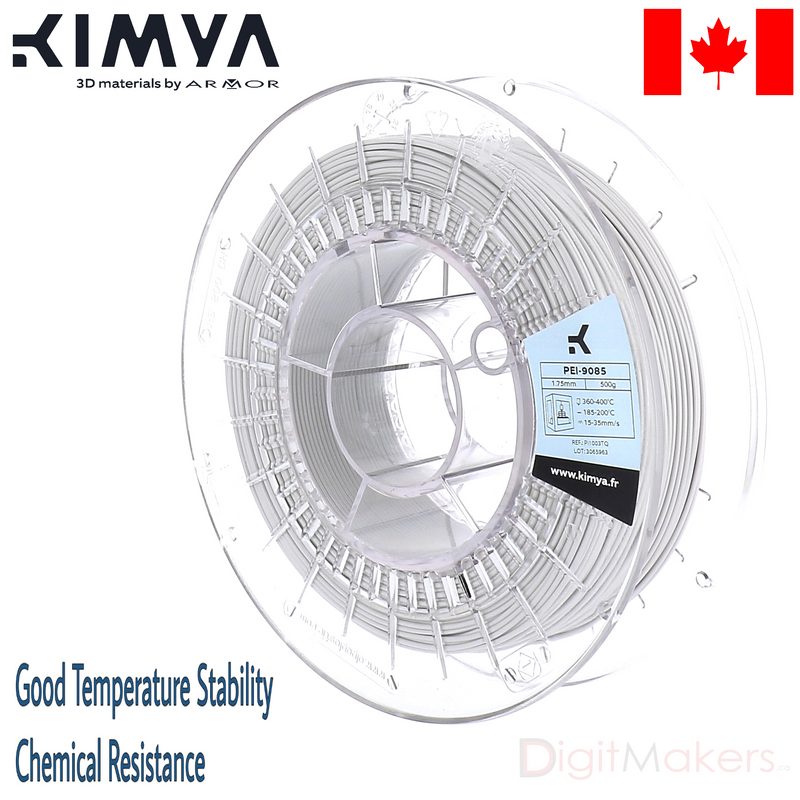

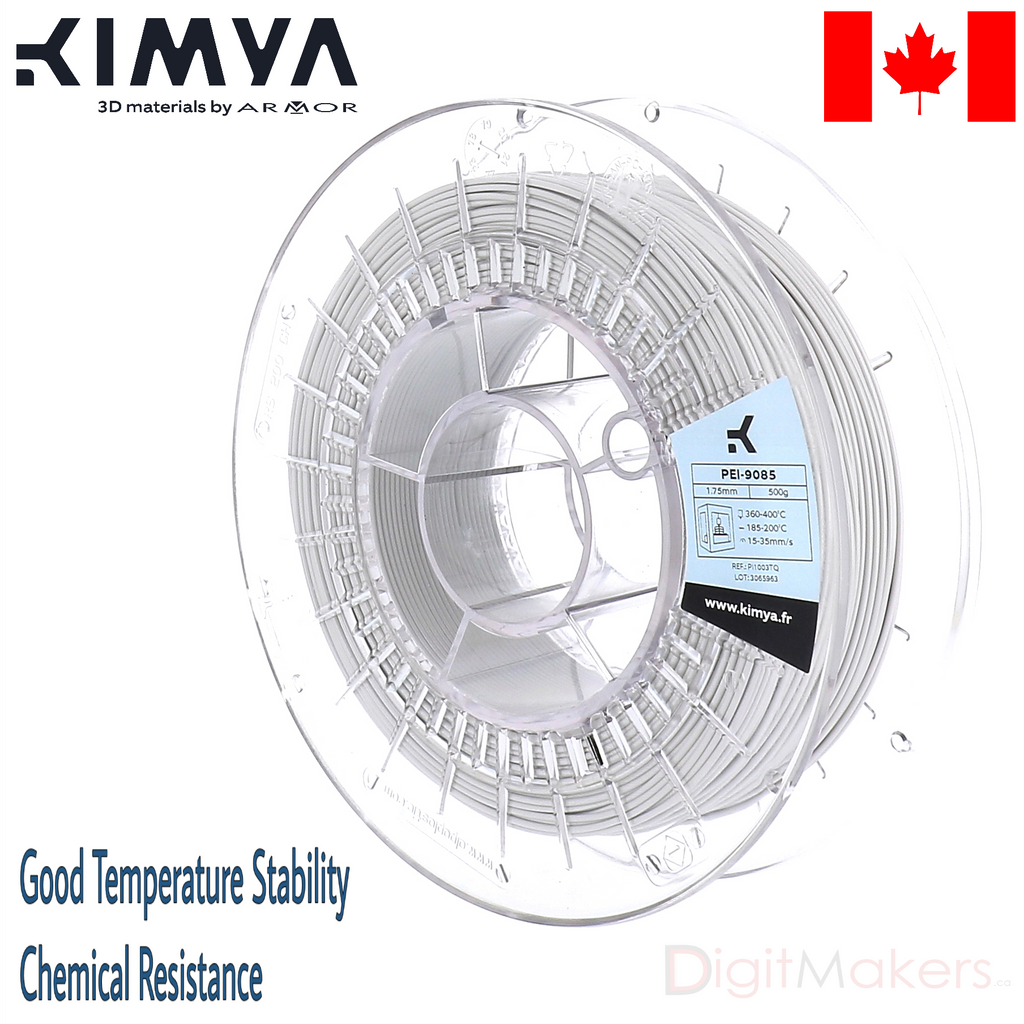

PEI-9085 Kimya 3D Filament

PEI-9085 Kimya 3D Filament

$270.99

The 3D PEI 90-85 filament offers the perfect balance between flexibility and mechanical strength. Good temperature stability Chemical resistance Kimya’s 2-year warranty. Diameter : 1.75mm Poids Net : 500g Color : Ivory Grey TECHNICAL SPECIFICATIONS DOWNLOAD THE PEI-9085 DATA SHEET DOWNLOAD PEI-9085 SAFETY DOCUMENT PRINTER SETTINGS PRIN...

Bluecast X10 - LCD/DLP 500g

Bluecast X10 - LCD/DLP 500g

$128.99

BLUE CAST X10 Excellent casting of small engravings both positive and negative. Suitable for all jewelry needs: from filigree to medals, as well from chaton settings to signet rings. - Excellent for stones presetting (improved elasticity). - No smell. - Negligible shrinkage (0.7% after 7 days). - Easy welding with wax. Excellent yield of det...

Bluecast Ceramic - LCD/DLP 500g

Bluecast Ceramic - LCD/DLP 500g

$158.99

BlueCast LCD/DLP Keramaster Castable: NO - Castability: nd Applications: models, rubber molds, high temperature applications (120 ° C) Compatible with: all LCD printers like Wanaho D7, Anycubic 3d, Micromake L2, X-Cube, Xayav V etc. (405 nm with 30 watt led or higher power) and with all LED UV DLP printers like as Asiga, 3DS Project 1200, Kudo T...

Bluecast Slash+ -500g

Bluecast Slash+ -500g

$158.99

BlueCast S + was developed for the new 3d printer Slash+ by Uniz. The base formulation is the same of the most performing BC resin: the BlueCast Original. The main features are the exceptional castability, the low shrinkage during printing and the low deformation over time. Thanks to this spec, BlueCast S + is actually the only resin for the je...

TPC-91A Kimya 3D filament Various Colors

$79.99

Kimya flexible filament of the family of thermoplastic elastomers copolyesters. FLEXIBILITY EASY TO PRINT LENGTHENING> 500% Kimya’s 2-year warranty. Diameter : 1.75mm Poids Net : 750g Color : Black/White/Grey TECHNICAL SPEC. DOWNLOAD THE TPC-91A KIMYA TECHNICAL DATA SHEET PRINTER SETTINGS PRINT SPEED : 44 mm/s EXTRUSION TEMPERATURE...