Accuracy of shape capture

Faster Client Delivery

Efficient Justification Process

Track, Repeat, Duplicate

Portable Clinic Solution

EinScan H2 – Advanced 3D Scanning Solution

Engineered for mobility and ease of use, the EinScan H2 weighs just 730g and features an ergonomic, portable design—perfect for on-site scanning in clinical settings or remote locations.

With its non-contact structured light technology, the EinScan H2 effortlessly captures high-precision 3D models of the human body, even allowing for minor movement during the process. This modern approach eliminates the need for messy, time-consuming plaster molds, offering a cleaner, more comfortable experience for both clinicians and clients.

At the heart of this powerful workflow is the EinScan H2—a next-generation handheld 3D scanner that brings unmatched scanning capabilities to O&P professionals.

Technical Highlights:

- 5MP Texture Camera

- 3 VCSEL Projectors

- Accuracy up to 0.05 mm

- FOV up to 780 x 900 mm

High-Resolution Texture Like Never Before

The EinScan H2 takes handheld 3D scanning to the next level with a powerful 5MP texture camera, enhanced accuracy, and three infrared VCSEL projectors. These upgrades work together to deliver stunningly photorealistic textures and highly detailed 3D data—perfect for applications where visual fidelity and precision matter most.

Hybrid Light Source

The EinScan H2 combines structured light and infrared technology, making it versatile for a wide range of scanning scenarios. It captures the intricate details of complex surfaces and dark materials with precision.

- LED light enables fast 3D scanning with accurate, high-quality data.

- Infrared VCSEL is ideal for capturing dark surfaces, the human body, and objects in bright-lit environments.

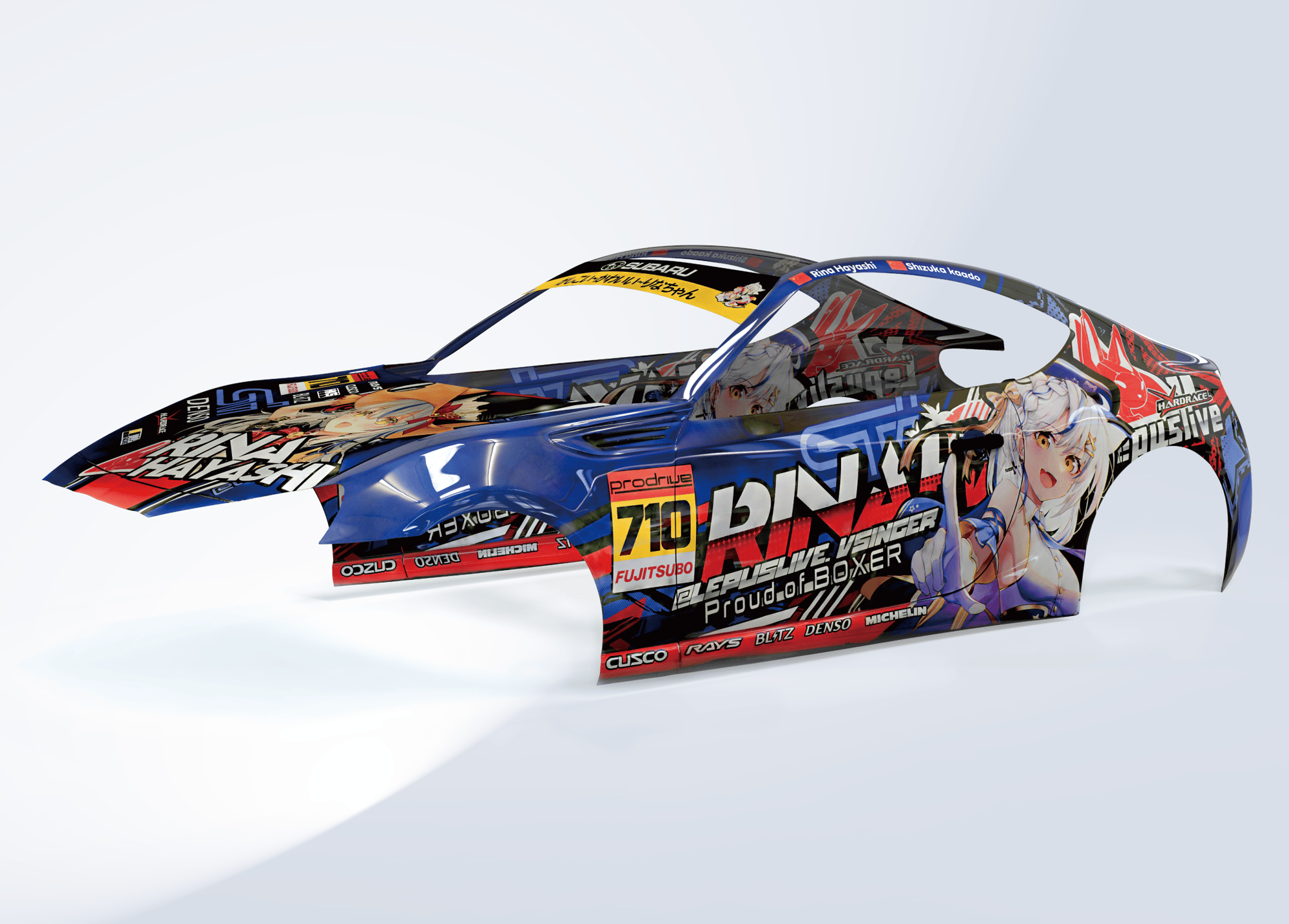

Photorealistic Texture

Equipped with a 5MP color camera, the EinScan H2 captures vibrant colors and detailed textures, combining them with precise 3D geometry to produce photorealistic 3D models. It's an ideal 3D scanner for cultural heritage preservation, art restoration, digital archiving, and other applications requiring high-quality textures.

High-Quality Data

Versatile, Marker-Free Scanning

The working distance adjusts from 200 mm to 1500 mm, making it versatile for both narrow and wide scenes, as well as objects of varying sizes. Its wide field of view, up to 780 × 900 mm, enables quick and efficient capture of large objects. Additionally, the marker-free scanning feature simplifies the process by using rich geometric features, eliminating the need for markers.

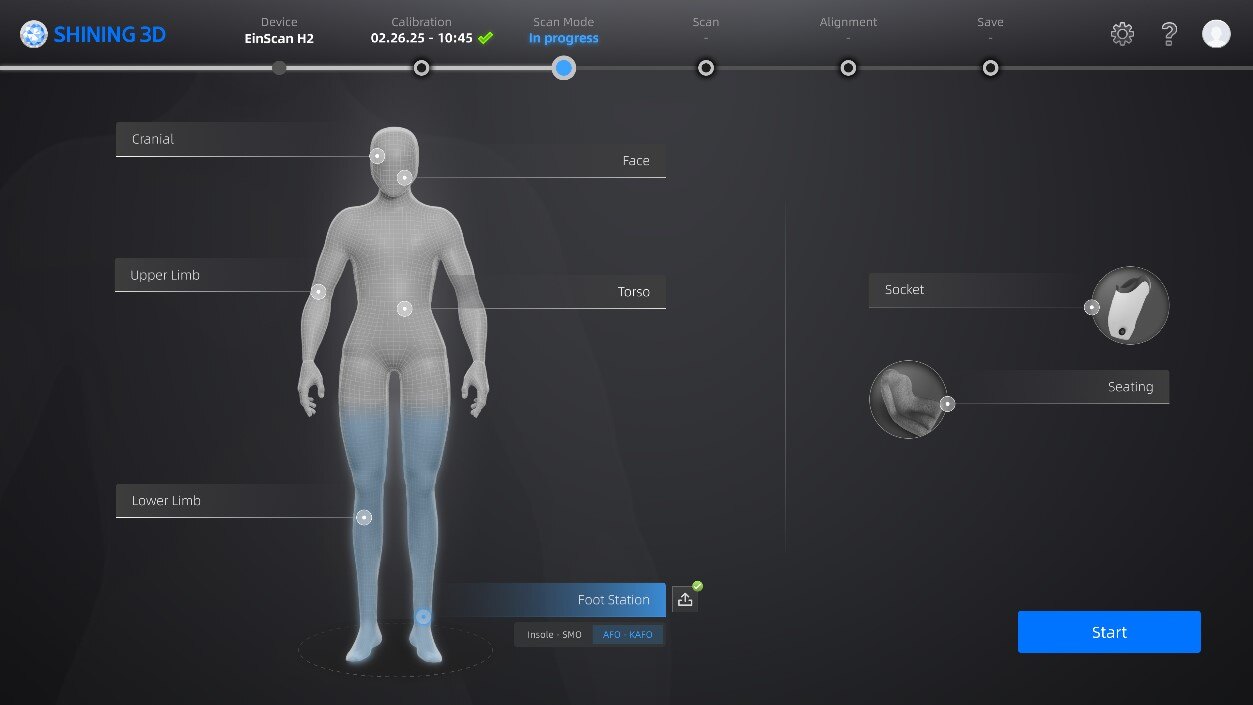

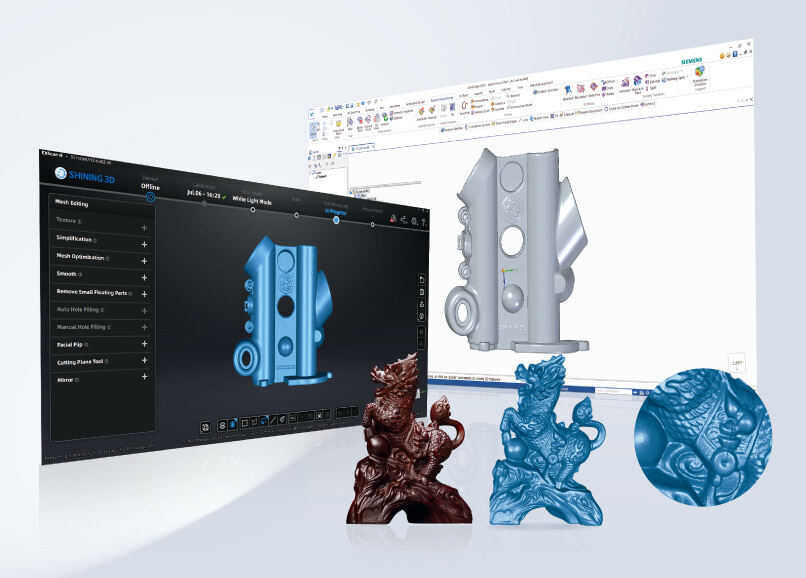

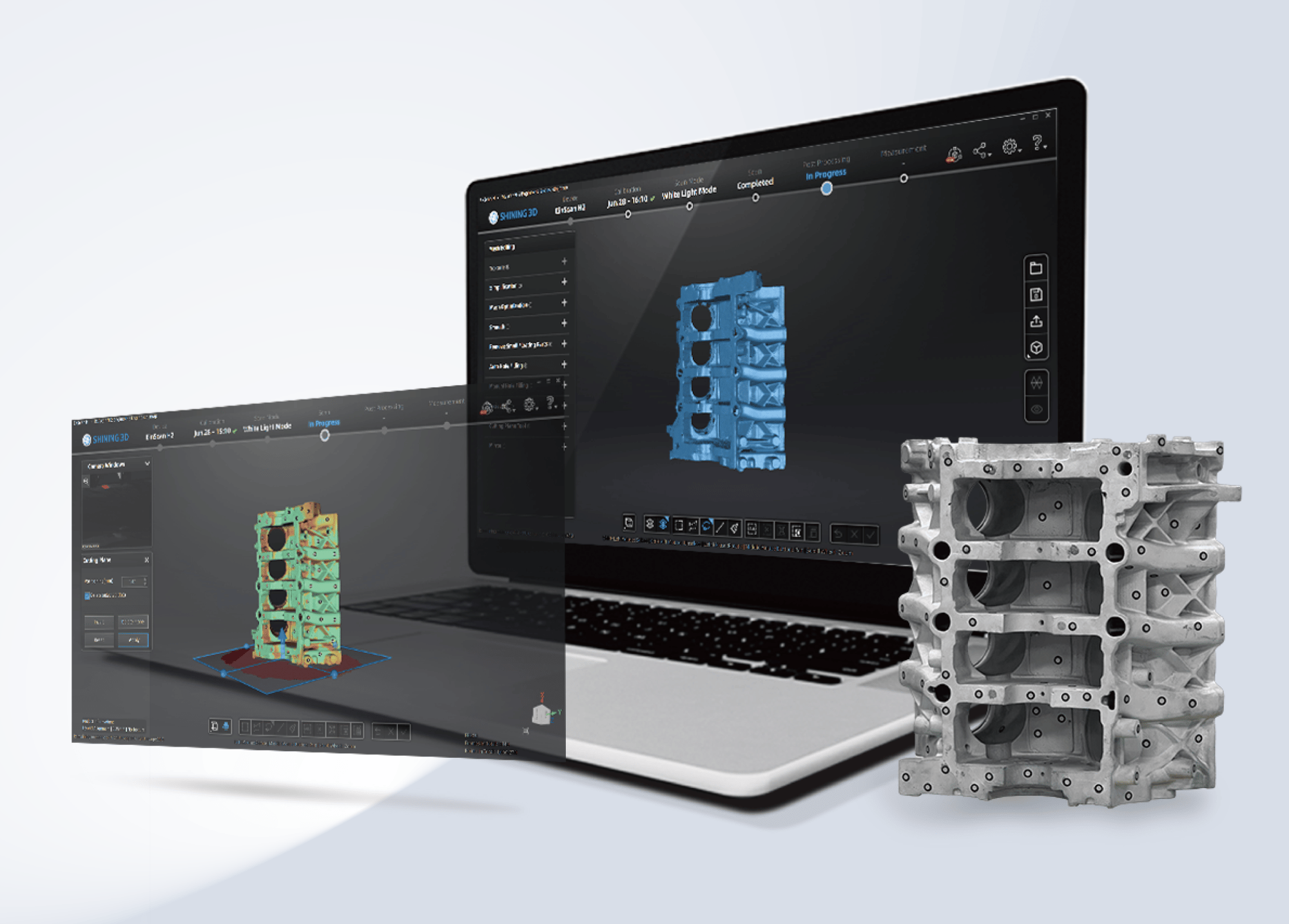

User-Friendly Software

The EinScan H2 provides a professional yet easy-to-use 3D scanning interface. It includes powerful post-processing tools, such as alignment, merging, and mesh editing, to ensure a smooth workflow from scan to finished model.

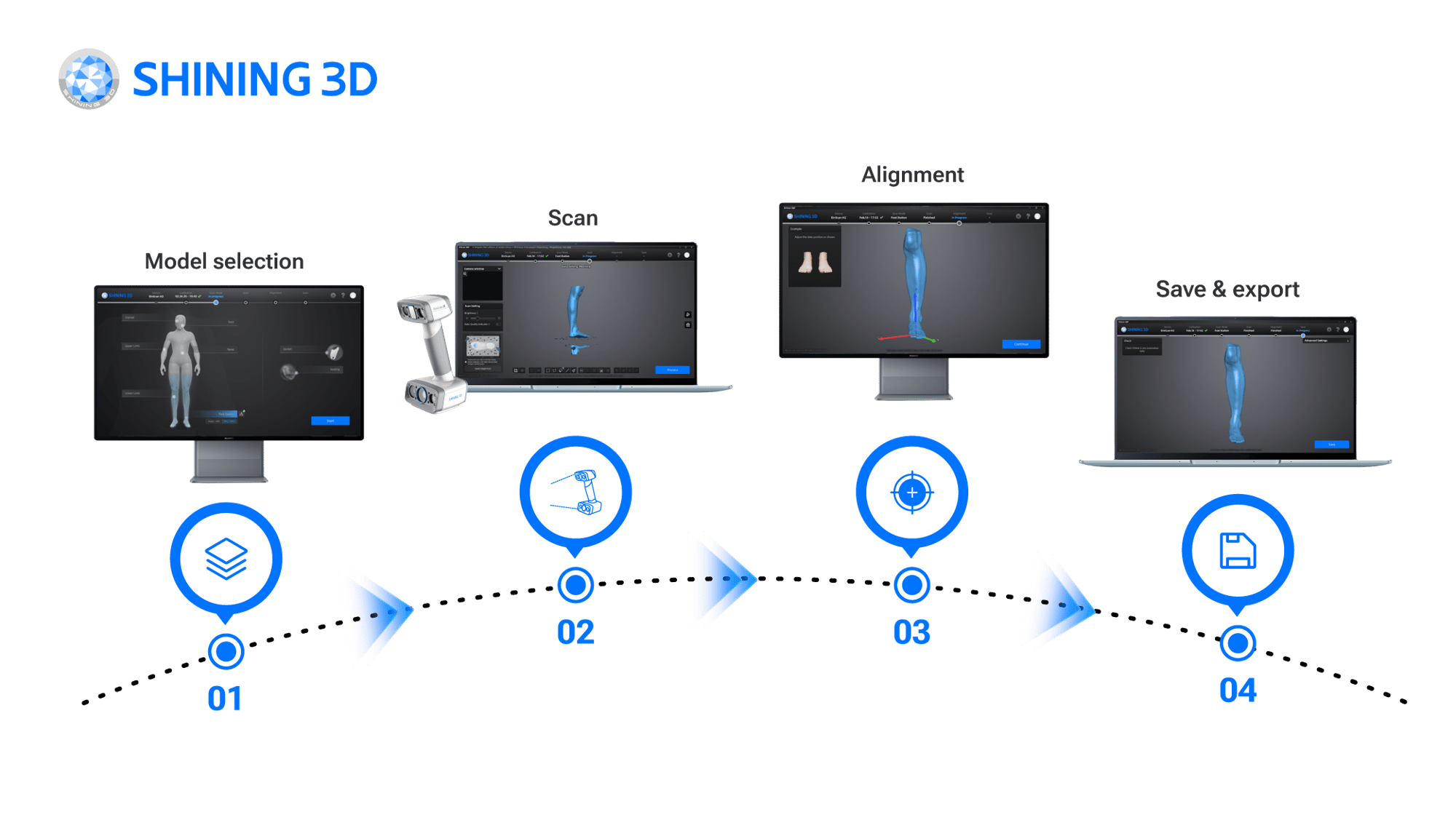

Streamlined Digital Workflow for Modern O&P Clinics

When combined, EXScan O&P and the EinScan H2 offer a complete digital solution that transforms the O&P workflow. Clinicians can scan, process, and transmit 3D models directly to labs, cutting out plaster molds, shipping delays, and inconsistencies. This streamlined digital approach enhances the quality of care and accelerates delivery times—without sacrificing accuracy or comfort.

Who Can Benefit?

Whether you're a clinician looking to enhance client outcomes, a lab technician aiming to streamline operations, or a facility manager looking for scalable, efficient solutions—this scanning system is designed with you in mind.

Final Thoughts

The future of orthotics and prosthetics is digital—and EXScan O&P paired with the EinScan H2 is leading the charge. With intuitive software, high-resolution 3D data capture, and a seamless digital workflow, these tools are redefining what’s possible in personalized patient care.

Ready to bring your O&P practice into the future? The EinScan H2 and EXScan O&P are the tools you’ve been waiting for.